About

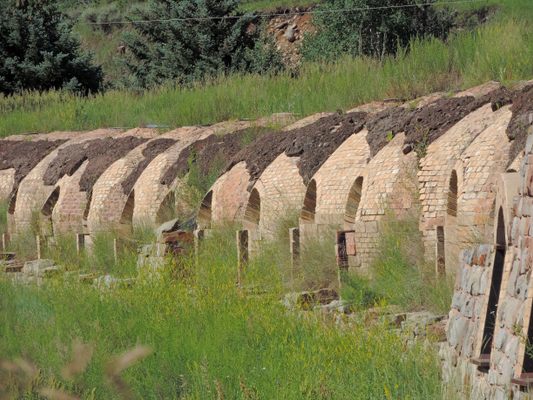

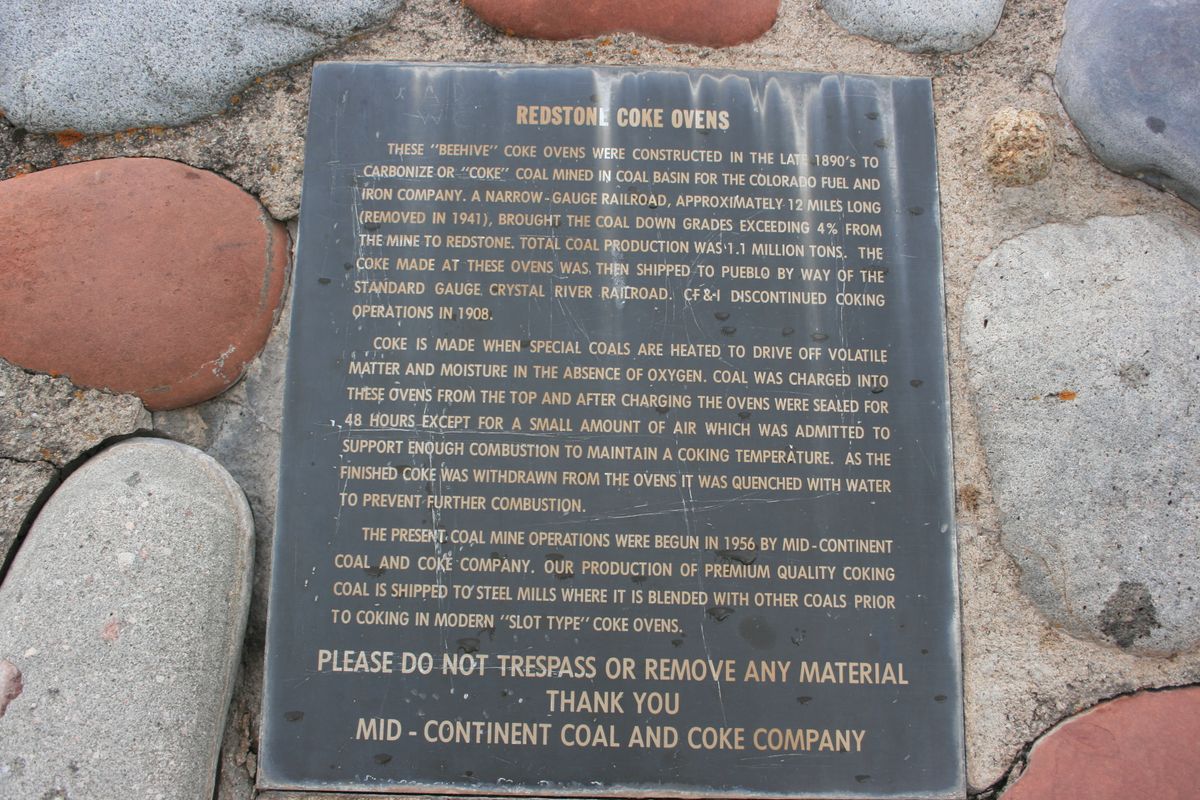

Coke is a nearly pure carbon product made from coal that is critical in many industrial processes, steel-making in particular. It is made by carefully heating coal in an oxygen-poor environment to drive off volatiles, all while not igniting the carbon. Typically the coal is placed in an enclosed chamber, a so-called coke oven, to smolder for about a day. Then the finished coke is doused with cold water to stop any further combustion, at which point it can then be shipped to the ultimate market.

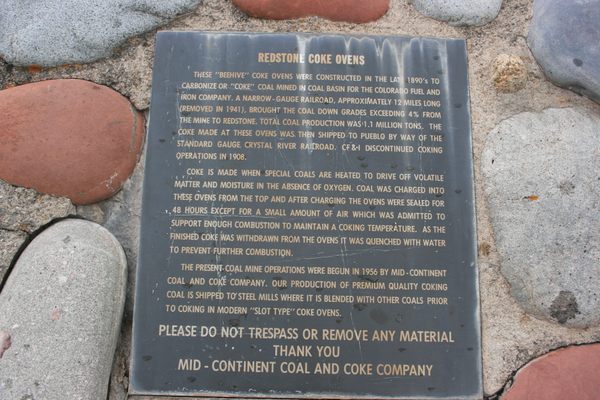

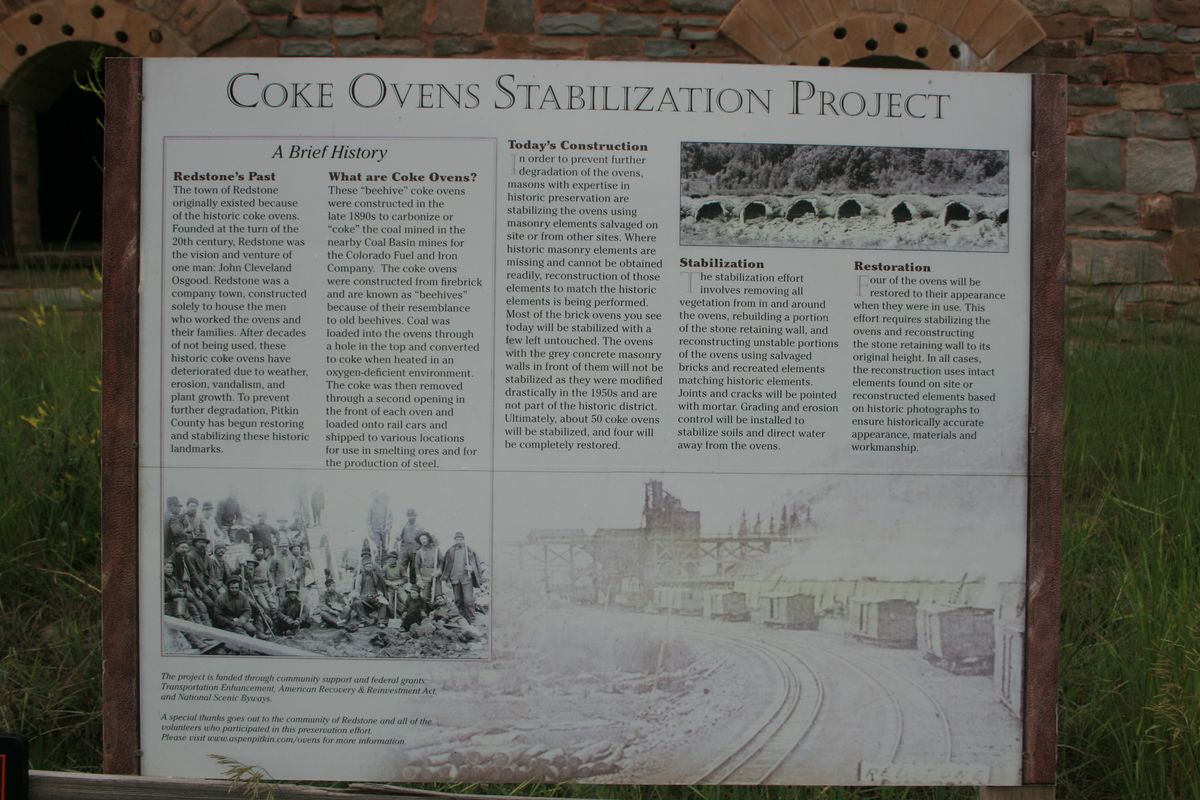

These ovens were built in 1899 by Colorado Fuel and Iron to process high-quality, almost ash-free coal that was ideal for coke manufacture. The deposit was in Coal Basin, some 2,200 feet higher, and the raw coal was brought down by a narrow gauge railroad, while the finished coke was shipped out by standard gauge. The adjacent Crystal River provided abundant cold water for quenching the hot coke.

Some 249 ovens were built and peak production briefly reached 6 million tons annually in the first years of the 20th century. In fact, some 10 percent of workers in Colorado at that time worked here. The large scale of operation was very short-lived, however; the company had financial problems by 1904, and then transportation to the intended end-use at the mill in Pueblo proved to be too expensive. The operation completely shut down in 1908.

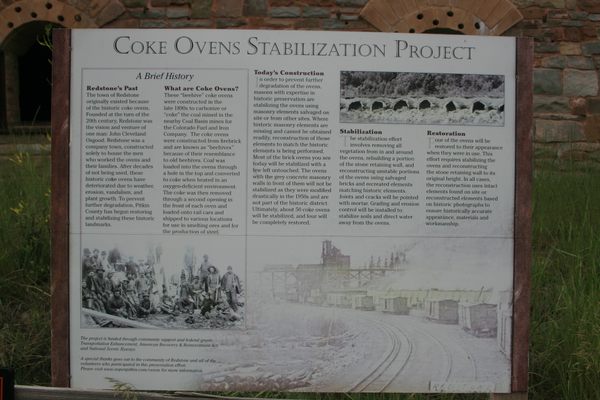

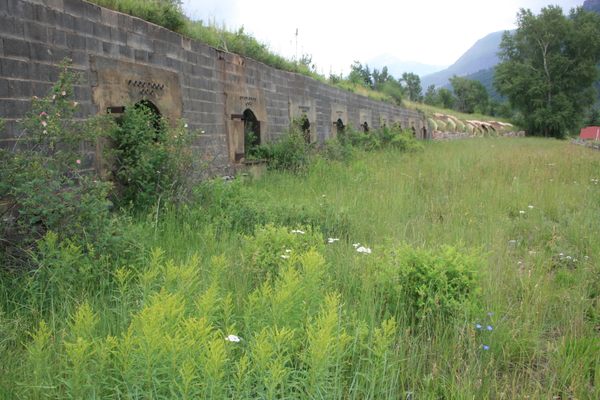

The abandoned ovens immediately began to deteriorate, and their deterioration was worsened by pillaging for materials. The steel supports were also salvaged in the scrap drives of World War II, which further hastened the destruction.

Not till 1990 were the coke ovens belatedly recognized as a historic site. At present 90 ovens survive reasonably intact, and in recent years several have been restored.

Related Tags

Know Before You Go

The ovens are off Colorado State Route 133 across from the village of Redstone, originally the old company town. There is parking right off the highway.

Published

October 19, 2023